Gas absorbers

Gas absorption refrigeration units.

Description

Yazaki gas-fired absorbers provide chilled water production using an absorption cycle.

The fluid used consists of a solution of lithium bromide and water, which is chemically stable, non-flammable, non-toxic, ecologically clean and not harmful to the ozone layer.

The solution is pre-loaded at the factory, where the machines are sealed and tested for ready use.

Chilled water is produced at a temperature of 7 °C, which is perfectly suitable for air-conditioning rooms during the summer.

Product Range

| MODEL | POWERCOOLING (kW) |

|---|---|

CH KG 30 | 105 |

CH KG 40 | 141 |

CH KG 50 | 176 |

CH KG 60 | 211 |

CH KG 80 | 281 |

CH K 100 | 352 |

CH MG 150 | 527 |

CH MG 200 | 703 |

FEATURES

Yazaki units can be operated by manual or automatic controls and can be easily activated remotely by remote control and adjustment units. The advanced electronic technology, which is widely used, guarantees high operating economy and reliability.

Yazaki units have three power levels (High-Low-Off). The efficiency at the different power levels is always high, so even operation at low speeds does not entail any loss of efficiency. A step control maintains the high performance of the multi-unit Yazaki by partitioning its operation, depending on the required heat load. A modular microprocessor constantly checks the load factor and automatically selects the optimal number of units in operation.

Yazaki units are equipped with cladding panels, which are perfectly impermeable and have surfaces treated to withstand atmospheric agents, even particularly aggressive ones. For heat dissipation, the units normally use water evaporative towers.

The basic models, available, cover capacities between 105 and 703 refrigerating kW, are modular in design and compatible with each other, allowing systems to be designed with multiple capacities.

Yazaki units are certified according to EC directives.

ADVANTAGES

-

Very low electricity consumption

The primary energy used is gas. Electrical energy is used exclusively for the operation of auxiliary control equipment, circulation of working fluids and heat disposal. An electrical transformer cabin is therefore not required.

-

Outdoor installation

Yazaki equipment is designed to be installed outdoors even in locations with particularly aggressive atmospheres, such as marine or industrial. The space previously used to house the heating unit is no longer required. It is, however, possible to install the units indoors, simply by taking into account the current regulations for thermal generators.

-

Ease of installation

Yazaki units are extremely compact. Their modular design facilitates transport and installation. All units, pre-filled with lithium bromide solution, are factory tested. Initial start-up operations are therefore very quick and easy and prevent any leakage of the contained solution into the environment.

-

High reliability

The famously high reliability of absorption units such as Yazaki is attributable to the limited number of moving mechanical parts. The very simplicity of design of such equipment is in itself a guarantee of reliability, as certified by the ASHRAE (American Society of Heating, Refrigeration & Airconditioning Engineers).

-

Quietness

The perfectly soundproofed Yazaki units are extremely quiet and vibration-free. They are also ideal for installation in city centres on terraces, attics, gardens and courtyards of commercial, industrial and service sector buildings.

-

Low maintenance

The limited number of moving mechanical parts reduces the number of components subject to wear and, therefore, to inspection and replacement.

-

Limited environmental impact

Yazaki units do not use CFCs and HCFCs, which are extremely harmful to the environment and are now banned. The feed energy used also limits the emission of harmful combustion.

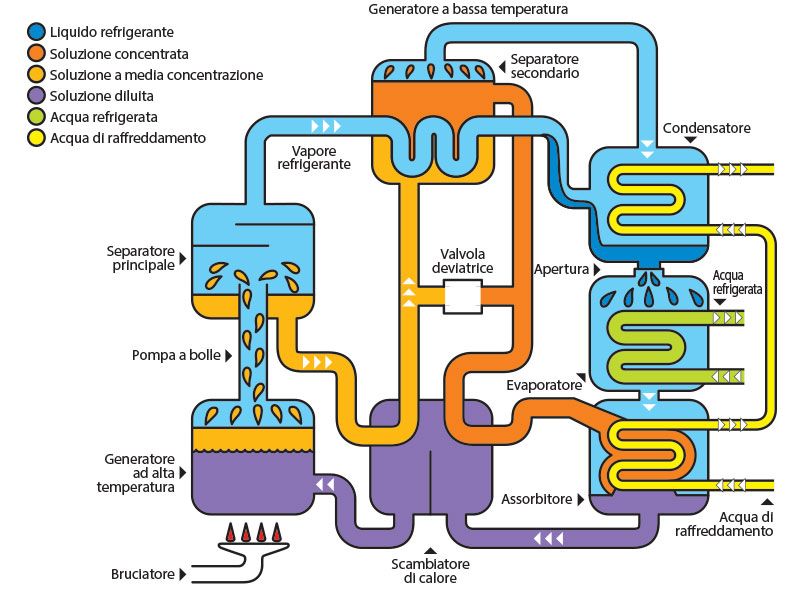

PRINCIPLE OF OPERATION

-

High-temperature generator

The gas burner heats the dilute lithium bromide solution contained in the high-temperature generator and the boiling process causes the cooling vapour, rich in small droplets of medium concentration lithium bromide solution, to reach the main separator. The lithium bromide solution is collected and pre-cooled by passing through a heat exchanger before being fed into the low-temperature generator.

-

Low-temperature generator

The hot refrigerant vapour from the separator re-heats (double effect) the medium-concentrated lithium bromide solution contained in the low-temperature generator. The refrigerant vapour then goes to the condenser, while the concentrated lithium bromide solution thus obtained is also pre-cooled by the heat exchanger before flowing to the absorber.

-

Capacitor

The refrigerant vapour reaches the condenser where it condenses on the surface of the cooling circuit coils. The condensation heat is removed from the cooling water and expelled through the evaporation tower. The coolant, collected in the condenser, then passes into the evaporator.

-

Evaporator

The pressure in the evaporator is much lower than in the generator and condenser due to the influence of the absorber. For this reason, the refrigerant liquid, once it enters the evaporator, boils and absorbs heat by evaporating on the surface of the coil of the water circuit to be cooled. The resulting refrigerant vapour then flows into the absorber.

-

Absorber

The low pressure in the absorber is due to the chemical affinity between the concentrated lithium bromide solution from the separator and the refrigeration vapour formed in the evaporator. The refrigeration vapour is absorbed by the concentrated lithium bromide solution as it laps against the surface of the absorber coil. The condensation and dilution heat is removed by the cooling water. The diluted lithium bromide solution is then preheated in the heat exchanger before returning to the generator.

Yazaki Gas Absorber Cycle